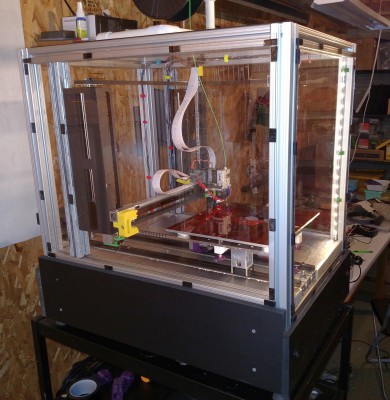

MegaMax was a great 3D printer, but it was time for some changes. He was difficult to transport because the electronics were in a separate housing with many cables to disconnect and reconnect, barely fit through doorways, and required a positively gargantuan enclosure to keep the temperature up to control ABS delamination. Though it hurt to do it, I tore him apart and did a complete redesign/build into a form that is more like what I would have done had I known anything at all about 3D printing when I started building MegaMax.

I reused what I could including a lot of the 8020 extrusions in the frame, the Z axis screw assemblies and drive belt, and the X and Z axis motors.

Changes include:

- ball screw drive Y axis with high torque motor- precise but noisy

- linear guides in X and Y axes instead of 1/2″ round guide rails and linear bearings

- SmoothieBoard controller instead of Arduino/RAMPS

- BullDog XL extruder and E3D v6 hot end

- RepRapDiscount graphic LCD control panel

- narrower frame design without giving up print volume- easier fit through doorways!

- polycarbonate panels to enclose the print area yet provide a clear view of the print

- electronics in a drawer for easy service and transport and neater appearance

- DSP motor drivers and 32V power supplies for X and Y axes

- Liberal use of screw terminals to make servicing easier

- Modular X and Y axes that can be removed for service and replaced in minutes.

SoM will be making his public debut at the Milwaukee Makerspace very soon…