We’ve been aluminum casting at the Milwaukee Makerspace since November, and I have cast several things since then. For simplicity, we started by using a lost foam casting method, wherein the form to be cast is fabricated in Owens Corning Foamular 150 (Styrofoam), and is then tightly packed in a reusable, oil bonded sand called petrobond. The molten aluminum is poured directly on the styrofoam, vaporizing it. Because the mold is made of sand, the surface texture on the cast aluminum part has the “resolution” of the grain size of the sand.

Ceramic shell is another technique often used in art casting. The positive of the form to be cast in metal is first created in wax, which is then dipped repeatedly in a silica slurry, that slowly builds up to the desired ½” thickness. The surface detail reproducible is much smaller/better, as the silica has a much finer “grain size.” The piece is then put in a kiln to burn out the wax and harden the silica, thereby forming an empty mold. Typically the mold is cooled, inspected for leaks, patched, and then is buried in regular sand. Note that to avoid fracturing the mold, it must be heated before pouring. With all these steps, this process is relatively time consuming and is also somewhat expensive.

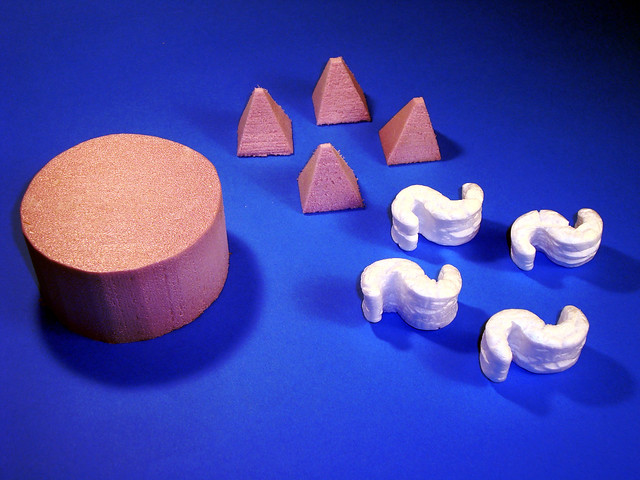

Recently, I read a blog post about a quick and low cost ceramic shell alternative that substitutes one or two coats of watered down “Hamiltons White Line Drywall Texture mix” for the tedious ceramic shell process outlined above. While I couldn’t find that exact product, 4.5 gallon buckets of Sheetrock brand lightweight drywall joint compound (DJC) are omnipresent. Note that some bags of quick setting drywall joint compound are actually just plaster, and cannot be substituted. I first assembled all the parts needed to make a quick test of the process. I decided to make some aluminum packing peanuts:

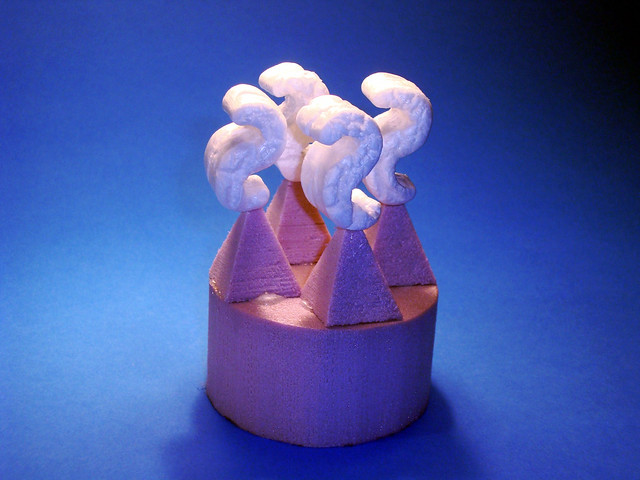

I hot glued the pyramid shaped sprues to the round cup and to the peanuts themselves:

I removed half of the 43 Lbs of DJC from the bucket, and poured in 10 lbs of water, taking care to mix it thoroughly with a spiral paint mixer connected to a drill. Then, I just dipped the whole styrofoam assembly into the bucket, let it dry overnight, and dipped it in a second time. Immediately after the first dip, I took care to brush the surface of any especially undercut areas, to prevent air bubbles from sticking to the surface. In the future, I may consider pulling a vacuum on the bucket of DJC to de-gas it. This may help prevent the formation of air bubbles on the surface of the styrofoam parts. In addition, I could have first dipped the assembly in surfactant. After two dips, the 1/8” thick shell on the assembly looked like this:

It was a week before the next aluminum pour at the Makerspace, during which time I poured a half ounce of acetone into the mold to dissolve the polystyrene packing peanuts and styrofoam, producing an empty mold. This step is only necessary when casting packing peanuts, as their polystyrene tends to rapidly expand out of the mold and catch fire, while the pink styrofoam (also polystyrene) is made for homes, and so is much better behaved. I buried the now-empty DJC mold in ordinary sand, and Matt W fired up the Bret’s furnace, melted a #16 crucible of aluminum, and poured it (Thanks guys!). After fifteen minutes, I pulled the mold out of the sand, and found the DJC was a little darker. The act of pulling the mold out of the sand an leaving it to cool over night left it somewhat cracked:

The DJC crumbled off so easily that I didn’t even need a brush. Also, I noticed that there is more yellowish surface tarnish on pieces left in the DJC to fully cool. I recommend removing the DJC immediately after the aluminum solidifies.

After making a few more, I’m almost ready to safely pack valuables, such as my “Marquis, by Waterford” crystal stemware:

Finally, check out the phenomenal surface detail that this process can reproduce. For scale, this peanut is 1.5” long. The surface texture on the front face is about ~0.002”!

Thanks to Jason G for this last photo. Also, a big thanks to Dave from buildyouridea.com for letting me know that one or two dips will do it!

Kevin is going *way* beyond the world of pink foam for his Aluminum casting… http://t.co/zryvV24FX1

[…] a reputation for only having members who are electronics enthusiasts. Well, in addition to the metal, wood, beer, water, whisky, fire, arduino, welding, odd, audio, casting, […]

[…] new building in January. However, the lighting was powerful and direct, which resulted in some pretty exciting shadows. Today, I set up four 400 watt equivalent, 105 watt (somewhat) compact florescent lights on […]

Bronze casting with ceramic shell building and the new modern techniques are of Great interest to me..I especially like the small scale and efficiency ..Looks Great !!!!

great stuff, has anyone tried using the dry wall paste as an investment shell in bronze casting? just wondering if it withstands the higher temperature?

I will send a pic of the placque I will cast next week.

Thanks for the idea. A. K.

I am casting a placque using refrigerator letters. What do you suggest I use as parting sand or release substance ? (( baby powder or PAM )

Still wondering about what if any results you have obtained pouring bronze??? Nothing posted below in response to those questions…

Definitely going to start doing this as opposed to fighting with sand/bentonite.

Kevin, this is astonishing. Guess what? I have been working with drywall contractors for like quite some years and this never popped into my mind.