When I arrived at the space Sunday, I had planned to work on a circuit board design in DipTrace. After I left, I had spent six hours rewiring a golf cart. Allow me to explain…

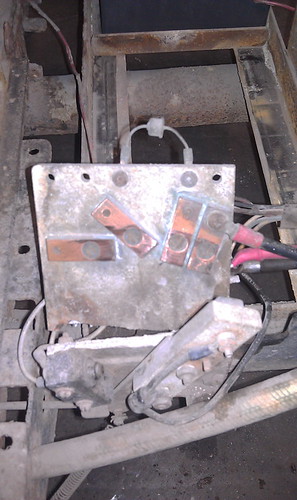

It all started when I went to take the trash out. I used the golf cart with the flatbed to ferry the cans out to the dumpster. After emptying the cans, I rode back and decided to charge the cart’s batteries. Tom and Rich had just returned from lunch and Tom suggested we swap out batteries instead. While swapping them out, we decided to also rewire them. While rewiring them, part of the cart broke. There’s a small white plate under the driver’s seat. It’s about 4″ x 6″, likely made of asbestos, and holds a series of copper contacts that a lever attached to the gas pedal slides over to select the speed of the cart. And it broke in two when we tried to tighten fix a wire on it.

We had a few options: try to mend the old, brittle plate, replace it with something new, rewire the whole thing, or scrap everything out for a solid state motor controller. Not wanting to adopt a new project or sacrifice a motor controller that could be better used elsewhere, I volunteered to try and fabricate a replacement for the broken part.

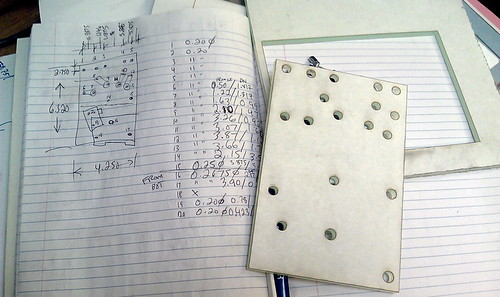

First I documented everything just the way it was. I labeled wires, took photos, scribbled down notes, etc. Next I went about removing the broken plate. There was probably more rust than metal on those bolts. Then I took a pair of digital calipers and a ruler and measured the locations and sizes of holes for each component. I considered using the CNC router or drilling a plate by hand, but the laser cutter seemed to be a much faster and precise approach. I drew up my replacement plate in CorelDraw and found a scrap of 1/4″ acrylic that matched the size and thickness of the old plate. After some tinkering with the printer driver and a dozen passes with the laser, I had a copy of the original in plastic form.

The next few hours were spent migrating the old parts over to the new one and wiring it back in. Right around 7:00 PM, I tied some batteries together and the thing leaped forward. A few more tests and it should be as good as new. Someone suggested that maybe the plate was asbestos to avoid heating issues so we’ll keep an eye on that too.

I just had a thought regarding the heating issue. If the heat does build up do you think that perhaps a piece of ‘Hardie Board’ siding might be a useful substitue for the asbestos? It may be slighly hygroscopic, but at the voltages prsent that may not matter.

So far heating hasn’t been a problem at all. Hardie board and other materials are always a Plan B should it become an issue.